100 hours

from first cut to first polish

This is what it takes to craft your commission from raw material.

The uppers, the interior and the soles.

All made from leather.

Hand: lasted

Hand: welted

Hand: stitched

With care, one pair will last one lifetime.

Explore the craftsmanship behind the scenes.

One single pair of hands

Hand lasted, hand welted and hand stitched footwear.

Following time honored tradition, passed down from shoemaker to shoemaker.

Hand: lasted

In the lasting process, the leather upper is stretched and nailed to the shoe last.

Hand: welted

The leather upper and interior footbed are stitched together with a strip of leather, called a welt.

When undertaken by hand, a tight, flush edge between welt and leather upper is achieved.

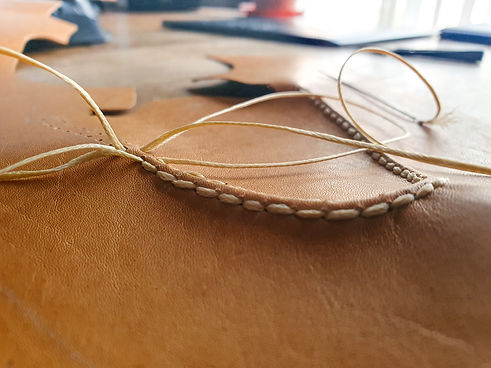

Hand: stitched

The leather outsole is hand stitched to the leather welt.

This allows for years of sustainable resoling.

The detail of a hand stitched outsole is characteristic of a quality commission.

Pattern drafting

The standard pattern, fitting the shoe last, is adjusted for fit or design.

In the case of MTD, the pattern is created based on your vision.

The conception of your commission starts here.

Cutting and sewing the uppers

The assembly of the leather upper takes time, especially for unusual patterns or those with many pieces.

The lining is checked to ensure that it fits into the upper, ensuring comfort.

Traditionally, these processes are known as the clicking and closing of the uppers.

Carving the structure

The insole; the footbed of your commission.

The toe puff and heel counter; maintain the shape of the leather upper.

Although unseen, these are the hidden heroes of your commission.

With care, they will make it last a lifetime.

Hand lasting

This is where your vision begins to take form.

Pulled and nailed, the the shoe last will pass on its curves to the leather upper that wraps it.

The first glimpse of your build can now be seen.

Hand welting

Sewing of the leather upper to the insole takes place through the use of a strip of leather, called a welt.

A traditional, elegant method, bringing together the interior and exterior components of handmade footwear.

To the welt, the outsole will be later stitched.

Adding support

Cork is added. Along with the insole, this will give comfort and mold to your foot shape over time.

Extra arch support is inserted, chosen from leather, wood or metal.

Traditionally, this process is known as bottoming.

Hand stitching

The outsole takes the daily wear of the path you walk.

It is shaped and stitched by hand to the welt. The stitching itself adds to the design element.

For those who prefer extra grip, a rubber half sole is layered on top of the leather outsole.

Outsole shaping

All outsole edges are hand shaped, transitioning from smooth curves to sharp edges.

Progressively finer grits of sandpaper are used to transform the rough leather into a silky smooth material.

Heel building

Discs of leather are cut, nailed and carved to create the heel.

Known as lift stacking, this simple process takes 1 full day.

Time is taken to ensure symmetry between each shoe.

Heel shaping

Shaping the heel curve, sanding and finishing it is one of the most challenging processes.

Special attention is taken to ensure that the heel cradles the leather upper, creating an unbroken transition between upper and heel.

Dying and waxing

Depending on design preferences, the leather outsole and heel are dyed.

Traditional shoemaking irons are used to apply hot wax to seal against water.

Finishing

The shoe last is removed, final inspection takes place, and laces are threaded.

Your commission is hand polished to a level that you choose.

The 100 hours ends here.

Handmade isn't better, just different

Compared to quality production footwear, handmade is not necessarily better.

Handmade simply gives more control to the maker, with the ability for fine adjustment through the construction process.

Handmade gives you the ability of choice.

Choice of leather, design, finishing. The choice to build a connection with the item that will carry you in the years ahead.

Only you will know.

Quality of material and construction

These can differ between handmade and production footwear.

Some of which will impact longevity and reparability.

Some of which will impact the possibility of finer design elements.

There is no right. There is also no wrong.

It all depends on what you want from your footwear.

Handmade

01

Leather footbed

Confirms to the foot shape

02

Carved leather insole

Traditional, time tested construction

03

Leather heel

Sustainable and repairable

04

Leather internal components

Adapts to curves of the feet

05

Handfinishing

Fine attention to detail

Production made

01

Fibreboard footbed

Rigid foot support

02

Glued insole construction

Time and cost efficient construction

03

Fibreboard heel

Compressible with wear

04

Plastic internal components

Rigid shoe form

05

Machine finishing

Ensures product consistency

Handmade is perfectly imperfect

The nature of handmade is simply that. Perfection in the imperfection.

The Japanese concept of wabi-sabi.

A natural asymmetry, a stitchline that is gently bent. All offset by the fine finishing that can only be found in handmade footwear.

The closeness of the leather upper to the shoe last. The curve of the heel to the outsole. The transition between curved lines to sharp edges. The unique pattern of the animal hide that you choose.

The character in your commission will never be replicated for anybody else.

If you want a product with perfection, then a quality production shoe is best.

If you want footwear crafted uniquely for you, then handmade is the only choice.